Welcome To N Machine Corporation

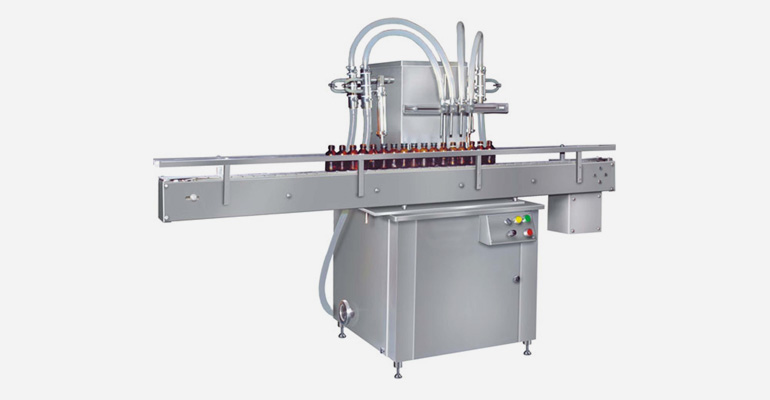

Liquid Filling Machine

A liquid filling machine is a type of industrial equipment used to fill containers with liquids. These machines are widely used in various industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and more. The primary function of a liquid filling machine is to ensure accurate and efficient filling of liquids into bottles, jars, vials, or other types of containers. Here are some key features and aspects of liquid filling machines:

Features and Capabilities

- Adjustable Fill Volume: Ability to set different fill volumes for different container sizes.

- High Accuracy: Ensures minimal product wastage and consistency in each filled container.

- Speed and Efficiency: Capable of filling a high number of containers per minute.

- Versatility: Can handle various container shapes and sizes.

- Hygienic Design: Made from materials like stainless steel to meet sanitary standards, especially important in the food, beverage, and pharmaceutical industries.

- Automation: Advanced machines offer automated features such as self-cleaning, automated capping, and labeling integration.

Applications

- Food and Beverage: Bottling water, juices, sauces, oils, dairy products, etc.

- Pharmaceuticals: Filling syrups, liquid medicines, vaccines, etc.

- Cosmetics: Filling shampoos, conditioners, lotions, perfumes, etc.

- Chemicals: Filling cleaning agents, solvents, industrial chemicals, etc.

Advantages

- Increased Production: Significantly boosts production rates compared to manual filling.

- Cost-Effective: Reduces labor costs and product wastage.

- Consistency: Ensures uniform fill levels across all containers.

- Safety: Reduces the risk of contamination and ensures compliance with industry standards.

Regular maintenance is essential to ensure the longevity and efficient operation of liquid filling machines. This includes routine cleaning, checking for wear and tear, calibrating sensors and valves, and ensuring all components are functioning correctly.